Mastering the Art of Soldering Roofinox Stainless Steel.

Here is a quick Audio Overview of what Roofinox soldering is about

Soldering stainless steel can be a challenging task, but when working with Roofinox, a specific type of readily solderable stainless steel, the process becomes more accessible and efficient. Roofinox stainless steel offers a unique combination of durability and aesthetics, making it ideal for roofing and facade applications. Let’s explore the key steps and considerations to achieve a professional-grade soldering result with Roofinox.

Why Soldering Roofinox is Different

Roofinox stainless steel has a specific surface that allows for easy soldering, unlike many other metals that can be more challenging. This characteristic makes Roofinox ideal for roofing and facade applications where waterproof joints are essential. The key to successful soldering lies in proper preparation, using the right tools and materials, and following the correct techniques.

Tools and Materials You’ll Need

To achieve a durable and clean soldering joint with Roofinox, ensure you have the following tools and materials:

- Soldering Iron: Choose a soldering iron with a minimum weight of 0.77 lbs to ensure adequate heat storage. For best results, use one that weighs 1 lb or more.

- Solder: Depending on the application, you can use a solder with 30%, 40%, or 50% tin-lead content. For lead-free applications, 100% tin solder is available.

- Flux – Roofinox FLM: This specialized flux is designed for stainless steel and is crucial for cleaning the joint and ensuring proper bonding. Avoid fluxes that contain chloride ions, as they can lead to corrosion.

- Soldering Stone (Ammoniac Stone): For cleaning the soldering bit.

- Cleaning Materials: Use fresh water and a cleaning tissue to clean the area before and after soldering.

Step-by-Step Soldering Process

- Preparation: Before starting, clean the surfaces to be joined. Ensure they are free of dirt, grease, and any foreign particles. For optimal results, maintain a soldering gap of around 0.0012 inches, which allows for maximum capillary action and gap filling.

- Tinning the Soldering Iron: Heat the soldering iron to approximately 480°F. Clean the tip using the soldering stone, then melt a thin layer of solder onto the tip to “tin” it, which improves heat transfer and prevents oxidation.

- Applying Flux: Use a flux brush to apply Roofinox FLM along the joint. This step is essential as it helps dissolve the passive oxide layer on the stainless steel, allowing the solder to bond properly.

- Tacking and Riveting: For joints subjected to mechanical stress, such as gutters, tacking and riveting is necessary before full soldering. Apply small amounts of solder to tack the metals together and keep them in place.

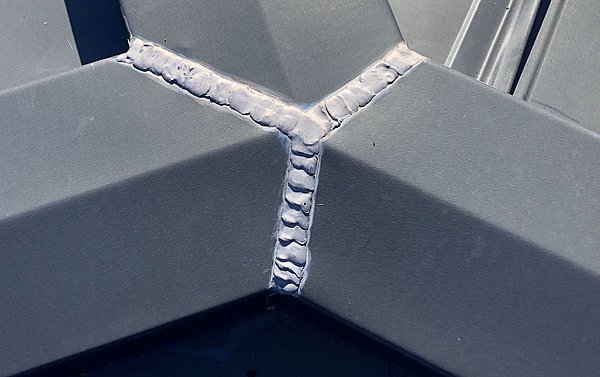

- Main Soldering Process: Once tacked, melt the solder on the iron and transfer it to the joint. Use continuous, smooth movements to draw a seam along the joint, ensuring the solder flows evenly for a durable, waterproof seal.

- Final Cleaning: After the solder cools and tarnishes, thoroughly clean the joint area with fresh water to remove any residual flux. This step is crucial in preventing corrosion and discoloration over time.

Benefits of Soldering Roofinox

Roofinox stainless steel offers numerous benefits for architectural applications, including its excellent solderability. The combination of a specialized flux like Roofinox FLM and proper soldering techniques ensures joints that are both aesthetically pleasing and functionally superior. Roofinox’s high corrosion resistance and malleability make it a sustainable choice for long-lasting roofing and facade projects.

Conclusion

Soldering Roofinox stainless steel may require some adaptation in your soldering process, but with the right preparation and tools, you can achieve outstanding, durable results. Whether you’re working on roofs, facades, or gutters, following these soldering guidelines ensures that your joints remain strong and waterproof for years to come.

By mastering these techniques, you’ll leverage the full potential of Roofinox stainless steel, ensuring a premium finish that meets both aesthetic and functional demands. Happy soldering!

For more detailed information and product specifications, check out the full Roofinox soldering guide or reach out to our technical support team.

Roofinox stainless steel Soldering Roofinox Architectural stainless steel soldering Roofinox FLM flux Waterproof stainless steel joints Durable soldering for roofing Stainless steel for facades Corrosion-resistant metal roofing Soldering techniques for Roofinox Sustainable roofing materials