Roofinox Tin Matt soldering: stop black stains and pinhole leaks

Tin Matt can solder great, but it’s unforgiving if you rush the basics.

Remember:

Rivet for strength. Solder for seal. Clean for looks.

Roofinox Tin Matt can solder great. But it has a tin surface, so your steps matter. Here are the big rules.

1) Flux: wipe it off every time

Flux helps solder flow.

But if you leave flux on the Tin Matt, it can keep reacting and turn the tin black.

Do this:

-

Use flux only where needed

-

When the seam is done: wipe + rinse with fresh water right away

2) Heat: solder colder

You are melting solder, not stainless.

If you solder too hot:

-

The tin surface can discolor (sometimes on the back side, sometimes both sides)

-

The stainless stays hot longer, so the solder stays liquid too long

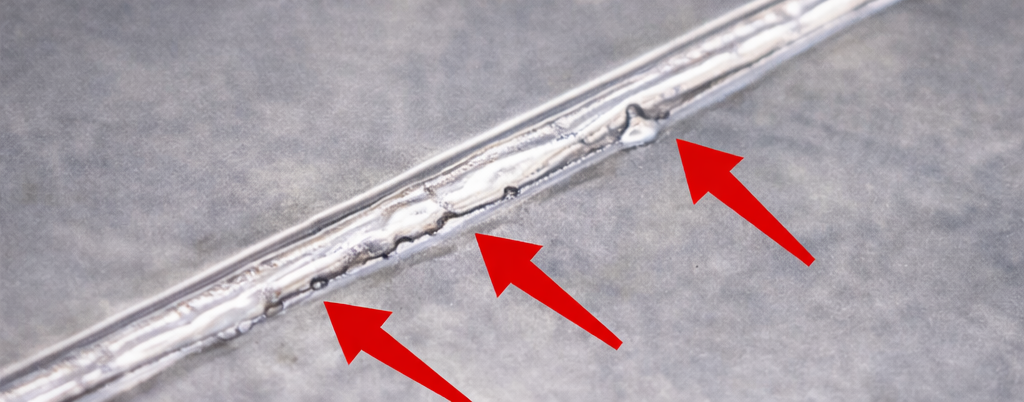

Result: the solder can pull out of the lap and leave pinholes.

3) Pinholes can leak by capillary action

Tiny holes or tiny gaps can move water through the joint. The leak can show up far from the seam.

Why it happens:

-

Too much heat = solder stays liquid too long

-

Solder runs thin or pulls out of the seam

-

Burned/dirty flux can also cause weak “wetting” and voids

4) Rivets + solder = the right combo

Rivets give strength.

Solder makes it watertight.

Without rivets, thermal movement can crack a solder-only joint.

With rivets, the joint stays stable and the solder can do its job.

5) Patina helps later (but don’t count on it)

Tin forms a patina over time and the roof trends toward a more even gray.

It can soften some discoloration, but it may not hide everything.

Roofer’s quick checklist

-

Don’t flood with flux

-

Heat only until solder flows

-

Don’t overheat the stainless

-

Rivet soldering joints always

-

Clean the seam area right away (wipe + rinse)